Maine Oar Making Kit

Professionally designed oars that you can build

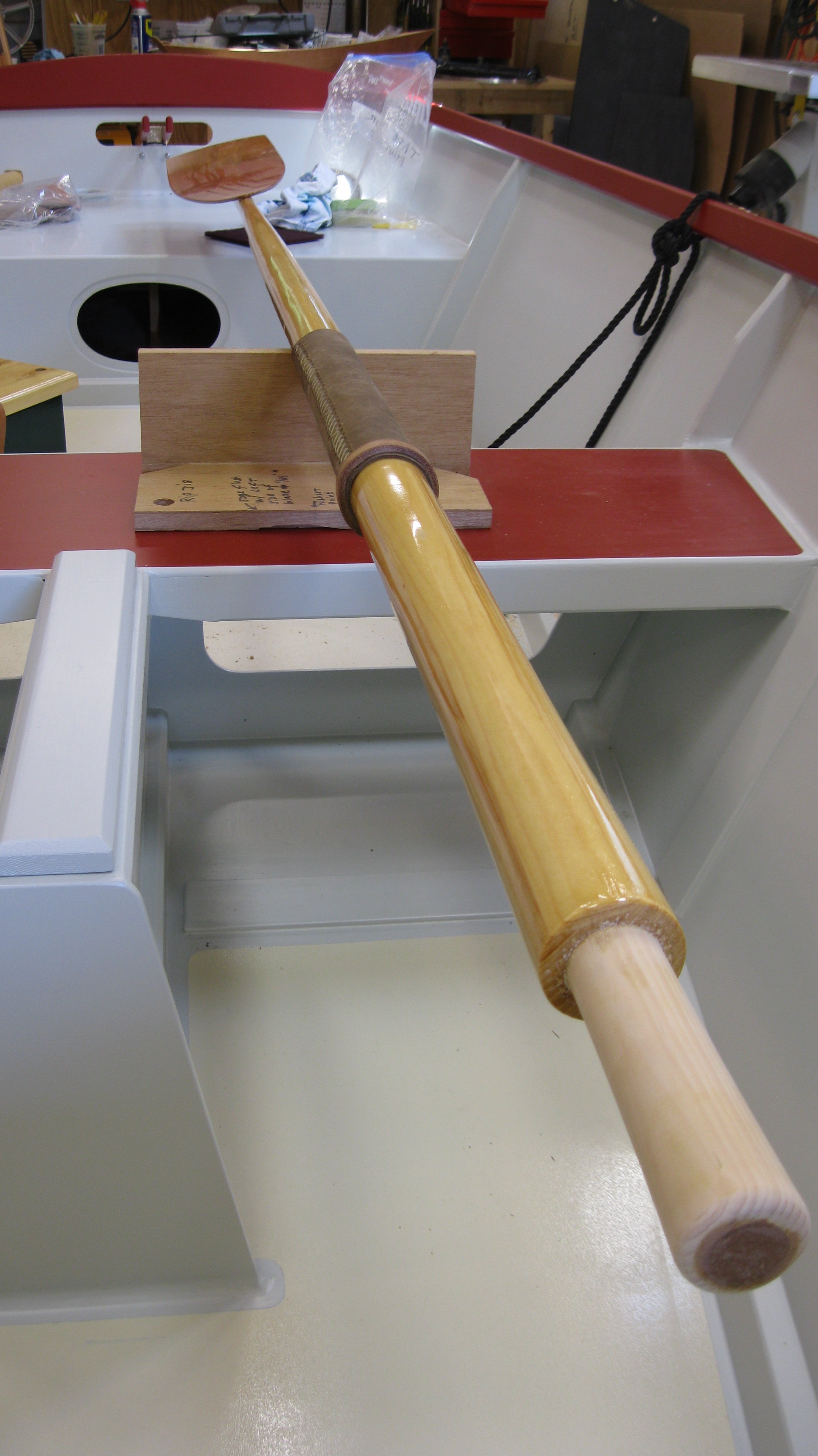

Looms (left) are cut out on our CNC router to dimension and with curve for spoon blades

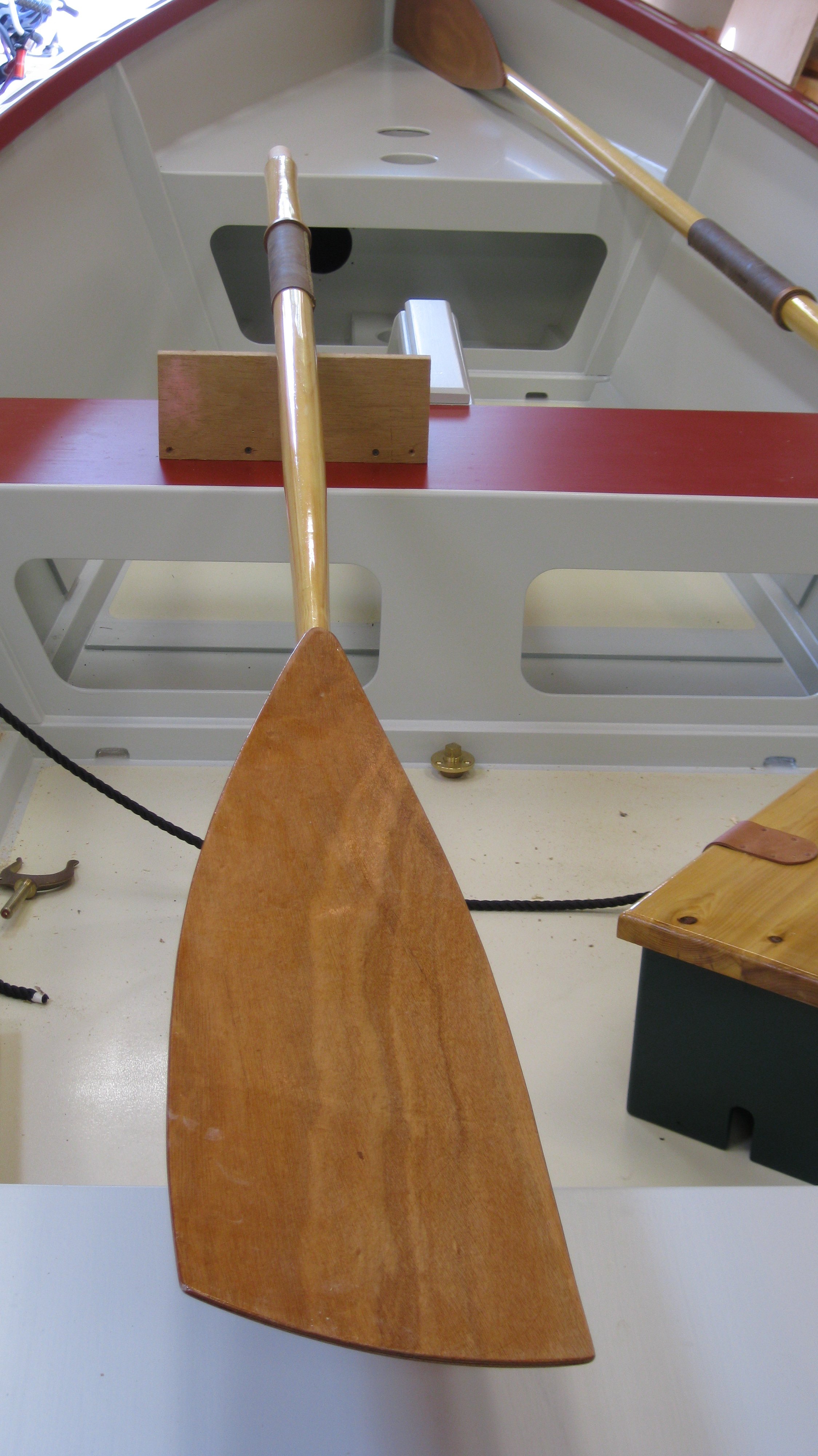

Blades are laminated in house from Okoume veneers and shipped ready to be glued to loom

The loom is tapered and glued to back of blade for strength and rigidity, making a very light oar

Making a professional set of oars from our kit is easy and fun. First, the loom (or shaft) is tapered according to the plans. The loom is kep square at this point but tapered so that the section at the neck is oval and the width of the loom on the back of the blade is 7/8” or so. The loom is rounded with the 8-siding gauge. Then, the blades are glued onto the lower, curved part of the loom - no fiberglass is needed. After the epoxy has cured, the loom is tapered and rounded on the back of the blade. Grips are shaped to suit your hand and the oar can be varnished. The leather kit comes from Oarsmanmarinetallow.com. The photos below show some typical results from our kit.

If you are interested in taking a class building your own oars, we offer an Oarmaking Workshop.

WoodenBoat Mastering Skills Videos: Oarmaking

Clint helped produce a comprehensive series of videos using the Maine Oar Making Kit. Please go to their Oarmaking Page to see a trailer and support Mastering Skills with a subscription for full access to this and their other excellent videos.

Oarmaking kits range from $350 to $495 per kit, which includes the wood components, an 8 siding gauge, and leathering supplies. When you inquire please indicate the boat type, oarlock span and we can tell you oar length and a price.