The details of how to design a yawl so that the tiller gets around the mizzen is an interesting topic. There are a number of tricks:

Using a line steering system: Here you can see Michael Storer's Beth Sailing Canoe with the tiller forward of the mizzen and the lines connecting to the rudder, which is out of the picture.

I'll add that there are a number of ways to do line steering. My Deblois Street Dory has line steering coming into the boat from a rudder yoke but there is not a remote tiller as in Beth. The Coquina is another example of line steering in which lines are attached directly to the rudder and pass through the transom, via a pulley system, and the steering line goes around the perimeter of the boat.

Using a long push-pull tiller: Here you can see James McMullen's Oughtred's double ender.

Using a curved, laminated tiller or split tiller

Using a normal tiller with an offset mizzen

For the Goat Island Skiff, we go with an offset tiller as in this model by a customer:

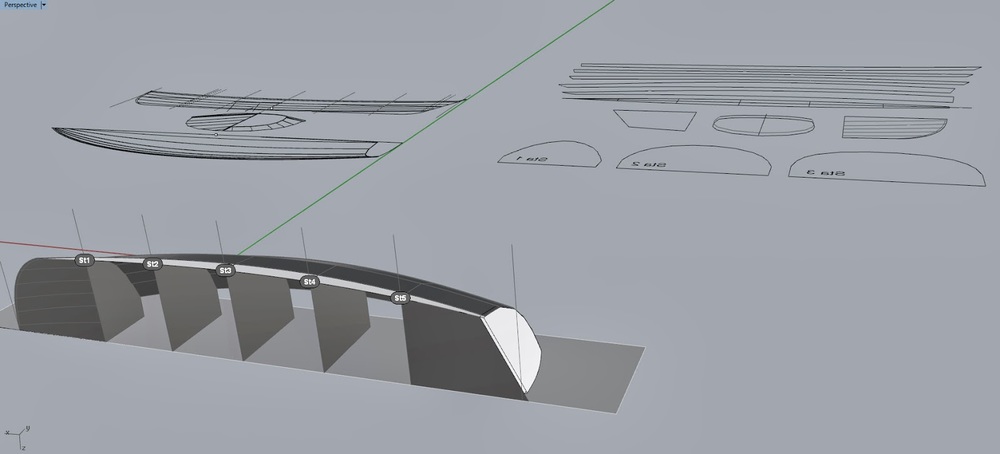

The other methods I mentioned just won't fit the situation we have in the Goat Island Skiff, mainly because there is not room for a split tiller and we want to keep the solution simple. We are deciding about just how much to offset the tiller. You can see above that the tiller will hit the mizzen before 45-degrees. The big question is how much room do we want to give the tiller to swing. In the pictures, we decided to test a 45-degree swing. That puts the mizzen a little further off the centerline than I'd like. This boat is very light and pushing a tiller than hard over makes the rudder act like a brake and the risk of losing so much speed that you can't get through the tack is something to consider. Then again, we don't need it so close that things feel claustrophobic. In the picture above of the offset mizzen, notice how little offset the mast is...the tiller must touch the mizzen pretty early. Does that give enough steerage for the helmsman when the push the tiller in the mizzen direction?

We'll have a solution soon after a full-scale mock up. The way we are doing this, collaboratively, is something I do on many projects. It always gets a better result because many thoughts and ideas can be sifted through. The more the merrier. Whatever the solution I draw up, the mizzen can always be moved a little more or less off the centerline according to the skippers preference. The important thing is to maintain the rake of the mizzen, which has been determined. My point is, that collaboration with designers, customers, and other folks with experience through the forums and boat shows can be an advantage in getting many thoughts onto the table and generating the best solution.