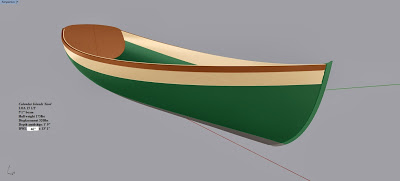

Specs

LOA 15' 6"

Beam 5' 2"

Anticipated Hull weight 150-200 lbs

Displacement ~520 lbs

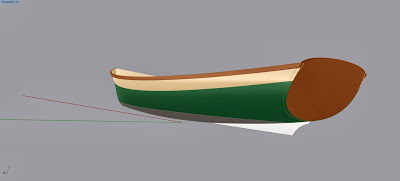

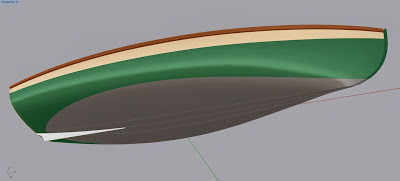

Here are some screen shots of the CIY model with lapstrake planking. The garboard is actually stitch-and-glued to the bottom, glassed, then the rest of the planks are plywood lapstrake with no fiberglass required. The bottom exterior is definitely oriented towards a lot of beaching as this is a sail-and-oar dinghy with an emphasis on sailing.

The waterline shows quite a bearing aft which should allow for a good planing when the wind is up and the crew is sitting aft and hiking out.

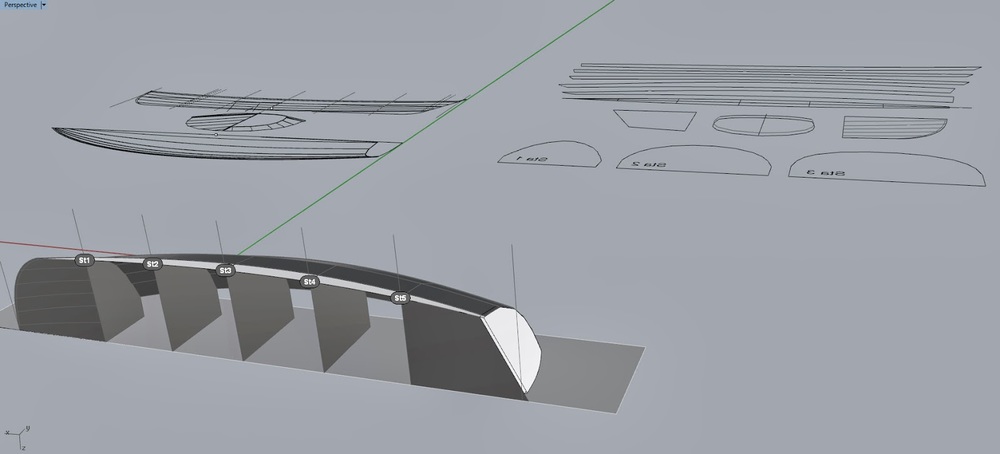

Now that the hull is complete, I can begin thinking about how to layout the interior structure with CNC cutting and kit building in mind but also so that the boat can be scratch built from just the plans or full size patterns.

I'll also sketch the rig but I bet folks know what the rig will be since its implied in the name. The CIY is named for the over 365 islands that dot Casco Bay. These islands and the sailing around them are the intended waters for this exciting boat.

The plan is to find a willing boat builder out there to build the first hull. I will sell the kit at my cost. Its a great way for someone to get into the boat they want for significantly less than what will be the retail cost.